Precision

CNC

Machining

Machining with purpose. Communicating with precision. Trusted by the world's leading companies for high-complexity, high-precision components. On-Time, Every-Time. ITAR registered, AS9100D certified, and NIST 800-171 compliant.

Production Parts. Prototype Speeds. Innovative. Inventive. Invigorated.

DEFENSE

AEROSPACE

SPACE

ENERGY

DEFENSE

Our ultra-high precision component manufacturing expertise, and ability to adapt to technological advances in military, help us lead the way in weapon development process.

AEROSPACE

At 4 Flutes Machining, we can take your project higher. We guarantee excellence by following the required high production standards and stringent safety controls of the aerospace industry.

SPACE

Like aerospace, the space industry requires impeccable quality and absolutely precision from prototype to finished product of CNC machined components. Our process is out of this world.

ENERGY

We power innovation by delivering high-precision components for generators and energy infrastructure, ensuring efficiency, durability, and reliability that keep the energy sector running—because when it comes to power, precision matters.

A PROVEN PROCESS WITH PROVEN RESULTS

IDEA

You bring us your vision—we bring it to life.

DESIGN

Our expert engineers use CAD software to create a 3D models of your concept.

PROTOTYPE

Using advanced CAM technology, we manufacture a prototype that aligns with the design specifications.

TESTING

Customer validates its functionality and ensures proof of concept.

PRODUCTION

Once the design is proven, we move to full-scale production, manufacturing high-quality batches of your parts.

QUALITY

In-process inspections during manufacturing and a final quality check using precision measurement equipment to ensure accuracy and consistency.

DELIVERY

Your completed, high-precision components are delivered on time, meeting YOUR standards.

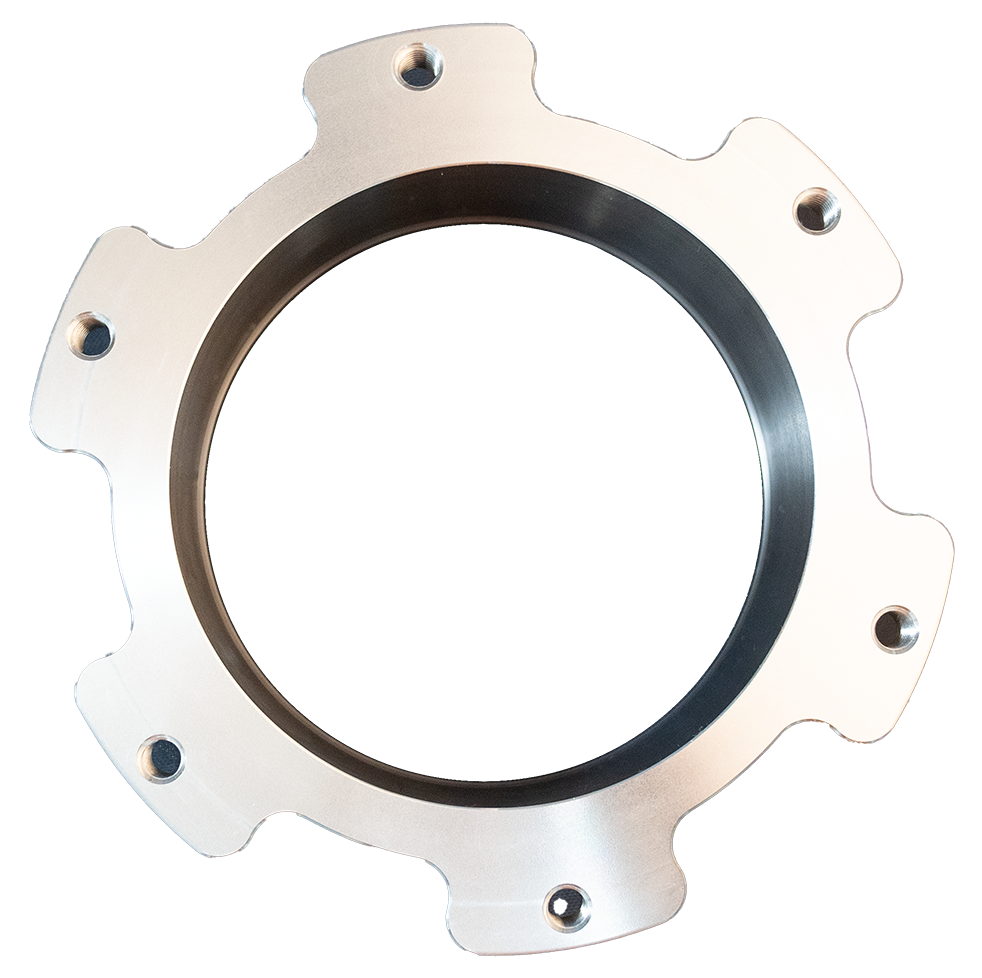

Milling

We use 3-axis machining for general part production and 4-axis and 5-axis machining for complex, high-precision components requiring advanced accuracy and efficiency.

TURNING

Our CNC turning capabilities include live tooling and sub-spindles, allowing for precise machining of complex geometries in a single setup.

Laser/Waterjet Cutting

Laser cutting delivers high-speed, ultra-precise cuts with minimal heat-affected zones, ideal for intricate designs. Waterjet cutting handles thicker materials with no heat distortion, ensuring clean, precise cuts on metals, composites, and more.

Milling

We use 3-axis machining for general part production and 4-axis and 5-axis machining for complex, high-precision components requiring advanced accuracy and efficiency.

TURNING

Our CNC turning capabilities include live tooling and sub-spindles, allowing for precise machining of complex geometries in a single setup.

Laser/Waterjet Cutting

Laser cutting delivers high-speed, ultra-precise cuts with minimal heat-affected zones, ideal for intricate designs. Waterjet cutting handles thicker materials with no heat distortion, ensuring clean, precise cuts on metals, composites, and more.

PRODUCTION MACHINING

Our production machining services provide high-volume, precision-manufactured parts utilizing robotically loaded 5-axis machining cells and pallet-changing horizontal machining centers to maximize productivity and ensure seamless, uninterrupted manufacturing.

CAD DESIGN

Our CAD design services transform concepts into precise 3D models and detailed blueprints, ensuring accuracy and manufacturability. Solidworks and Fusion 360. Out of AS9100D Scope

CAM DESIGN

Our CAM (Computer-Aided Manufacturing) programming transforms CAD designs into precise machining instructions, optimizing toolpaths for efficiency and accuracy. MasterCam and EspritCam.

PRODUCTION MACHINING

Our production machining services provide high-volume, precision-manufactured parts utilizing robotically loaded 5-axis machining cells and pallet-changing horizontal machining centers to maximize productivity and ensure seamless, uninterrupted manufacturing.

CAD DESIGN

Our CAD design services transform concepts into precise 3D models and detailed blueprints, ensuring accuracy and manufacturability. Solidworks and Fusion 360. Out of AS9100D Scope.

CAM DESIGN

Our CAM (Computer-Aided Manufacturing) programming transforms CAD designs into precise machining instructions, optimizing toolpaths for efficiency and accuracy. MasterCam and EspritCam.

Proudly American Made

4 Flutes Machining, based in Vicksburg, Michigan, is committed to strengthening the American economy and supporting the Warfighter through precision CNC machining for government and defense applications. We proudly source DFARS-compliant materials, employ a skilled local workforce, and partner exclusively with U.S.-based suppliers. As a ITAR Registered, AS9100D Certified company, we are equipped to handle a wide range of contracts with the highest standards of security and precision.