Capabilities

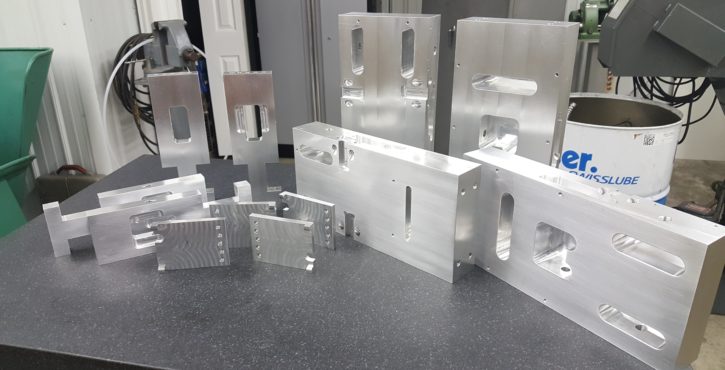

At 4 Flutes Machining, we know the value of being a one stop shop for our custom machining clients. As our business has grown, we have added on new equipment and machines that can be used to complete nearly any small run (5-500 pieces) machining project from concept to finished product. If you have any questions about the custom machining capabilities we have available, contact us!

Our axis tooling machines were the backbone of our company. They got us to where we are today. We have 4 vertical milling machines with travels ranging from 15×20 up to 24×42 inches.

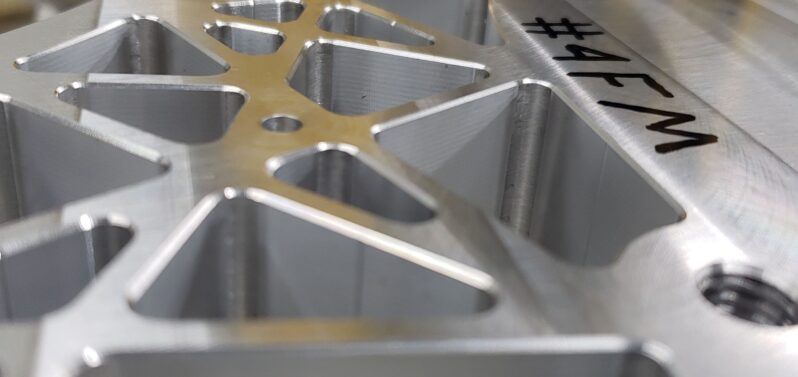

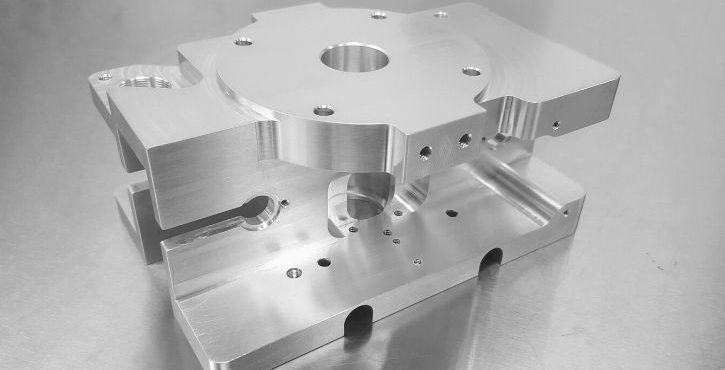

The exceptional growth of 4 Flutes, enabled us to take the next step in machining technology to create more difficult parts efficiently that are not achievable with 3 axis machines.

Our 5 axis machines are the pinnacle of our business and the represent the direction we are heading. About 98% of the world’s machining work can be done on 3 or 2 axis machines. And now, we are capable of doing the 2% of the work with 5 axis milling, opening up a lot of opportunity when it comes to extremely difficult part and component manufacturing.

These lathes are a must have machine with today’s manufacturing technology. In fact, nearly half of the parts that are made in our machine shop see the lathe.

Manual milling creates an upright cutting movement that doesn’t require modern programming resulting in quick turnaround times for parts.

Manual turning uses a rotating chuck to hold the work piece while a stationary tool is used to remove material.

Now more than ever, it’s important to work with a CNC machining company staffed by dedicated employees who show up ready to work every day. If you need a project done in a timely manner, partner with 4 Flutes Machining today.