Services

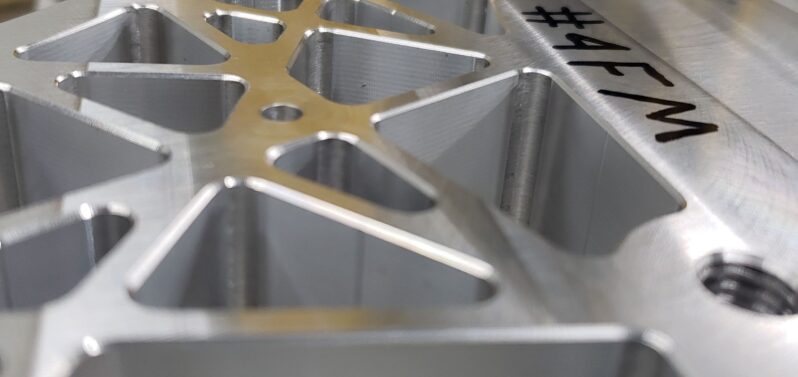

4 Flutes Machining is committed to partnering with you through each step of the production process. We provide prototype machining services and engineering solutions to your needs. Our specialty is small scale (5 – 500 pieces) production. If you have any questions about the prototype machining services we offer, contact us today!

3 axis for general parts, 4 and 5 axis for high-precision components.

Machining cylindrical parts is done by turning on a lathe.

Uses electrically charged wire that cuts almost perfectly square corners that otherwise wouldn’t be achievable with traditional machining methods.

Utilizes a graphite or copper electrode that is machined to the inverse of the part profile. It will burn material away that give the part geometry that can’t be achieved traditionally.

Surface grinding involves securing a part and using an abrasive wheel to take small amounts of materials off of the part to create surface finish, flatness, and parallelism. ID/OD grinding is inside diameter and outside diameter. An abrasive wheel is used to remove small amount of materials to achieve surface finish, diameter, concentricity, circularity tolerances.

We don’t just design and build a prototype concept, we can even assemble it before it lands on your doorstep.

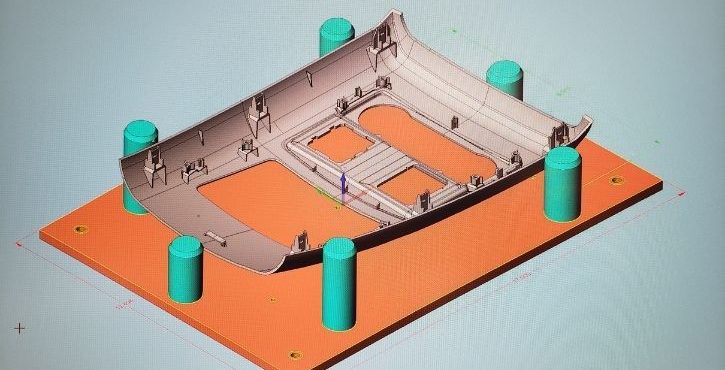

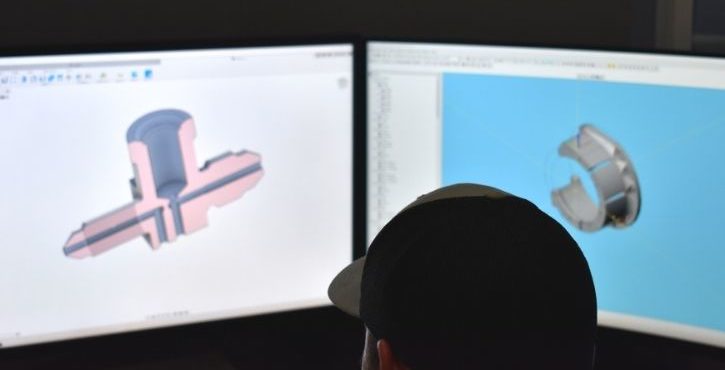

As described on the capabilities page, we specialize in bringing your concept to life with our CAD design service. If a client has a concept of a prototype part, 4 Flutes can take your sketch and make it a 3D model.

Taking the CAD design and selecting features on the part and creating tool paths that then generate G-code that the machine tool will run from.

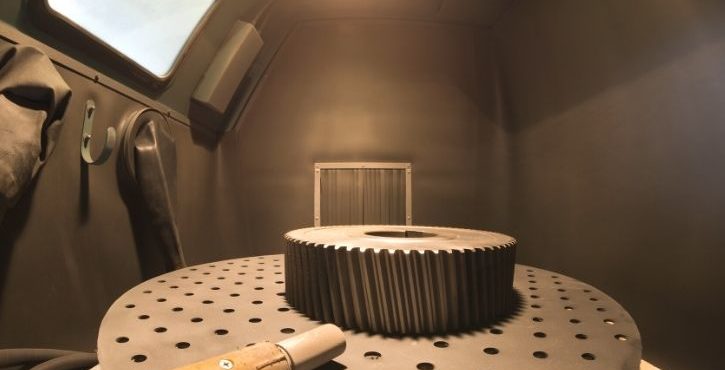

We use a wide range of abrasive medias to achieve a particular specification as required by the client.

Running batches from 20 to 20,000 for a specific part with quality checks in pre- through post-process.

Now more than ever, it’s important to work with a CNC machining company staffed by dedicated employees who show up ready to work every day. If you need a project done in a timely manner, partner with 4 Flutes Machining today.